We are the only Canadian conveyor belt manufacturer

Tough belts for tough

Canadian industries

Get instant access to technical information, splicing guidance and powerful calculation tools for improved operational efficiency — anytime, anywhere.

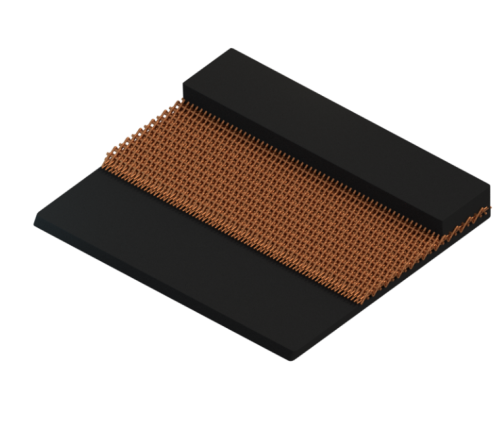

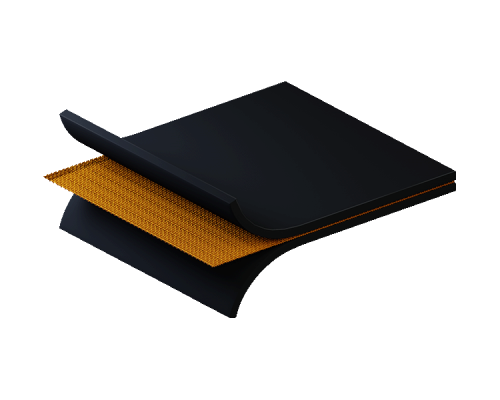

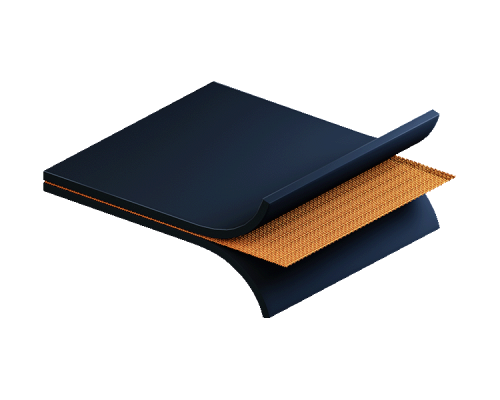

Discover X Series: a premium line of single and dual-ply construction conveyor belts

A Leading

Manufacturer

We're looking to maintain sources of raw material for the future where ever possible using bio-based materials and also using recycled materials in the product without detriment to durability.

-

Made in Canada

Built to Last -

Supported by

Canadian Distributors.

Proudly made in Canada

At Fenner Dunlop, we take great pride in being Canada’s only conveyor belt manufacturer. Our state-of-the-art facility enables us to produce high-performance textile and steelcord conveyor belts locally, ensuring superior quality, shorter lead times, and a reliable supply for Canadian industries. We are also expanding our capabilities to manufacture PVG belting, further enhancing our product range.

Case Studies

We are famous for manufacturing the longest lasting conveyor belts in the world, but we don’t want you to simply take our word for it. Please check out some real-life case studies below.